DEtachlog

Patented technology

- Sensor-based data measurement

- Unique ultrasound damping spectroscopy

- Temperature, humidity, magnetometer, accelerometer

- 15 years of research at the Federal Institute of Technology in Zurich (ETH)

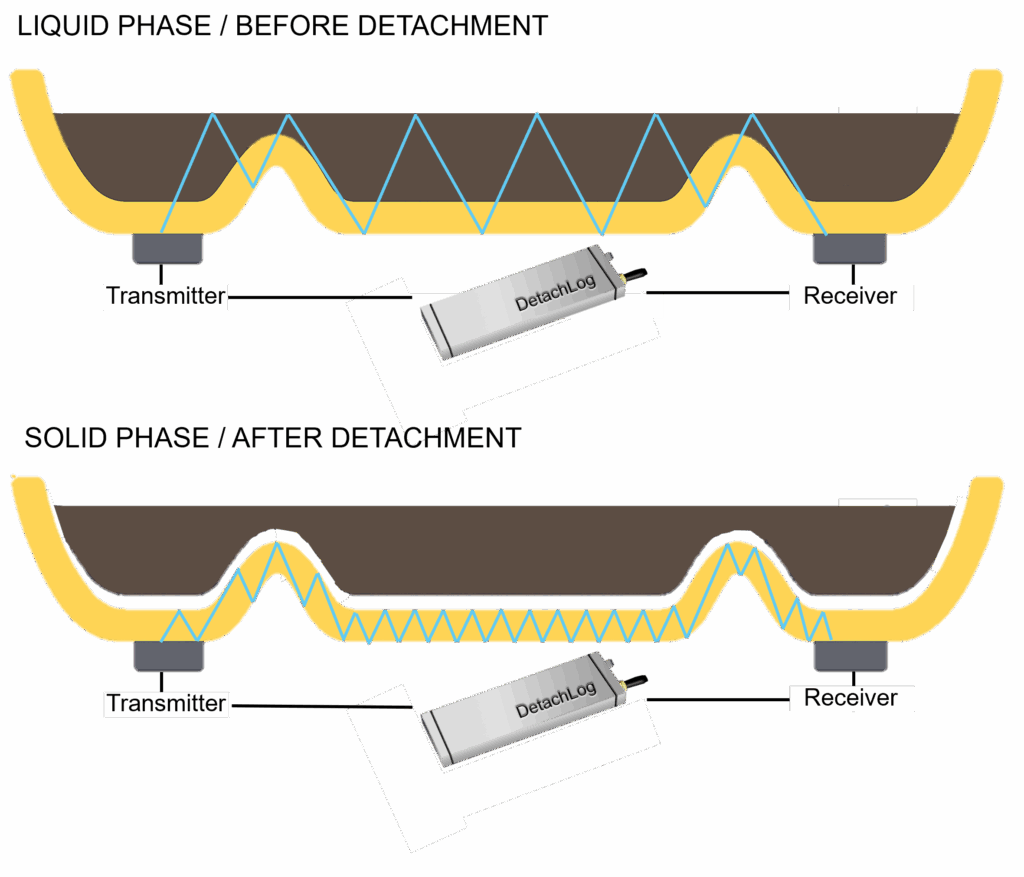

How it works

- Measures the ultrasound wave between transmitter and receiver sensors installed on a mold filled with chocolate

- The ultrasound attenuation stands for a highly accurate fingerprint of the chocolate structuring and crytallization quality from liquid phase to solid phase

8 parameters measured

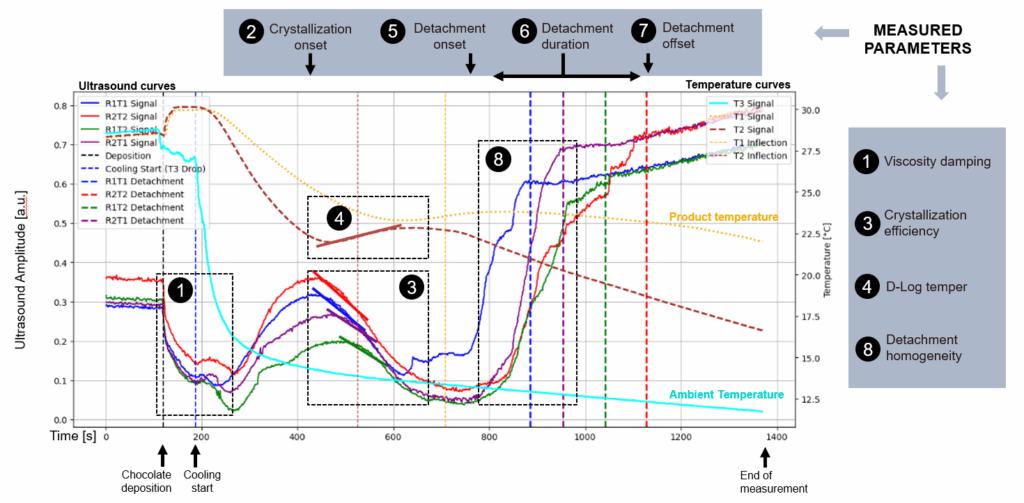

Viscosity parameters

1- Viscosity damping: accurately reflects the viscosity of the tempered mass

Crystallization parameters

2- Crystallization onset

3- Crystallization efficiency

4- D-Log temper: Authentic temper index

Detachment parameters

5- Detachment onset

6- Detachment duration: optimal cooling time

7- Detachment offset

8- Detachment homogeneity

Main benefits

Product quality

- Reduce surface defects

- Maximize gloss

- Optimize shelf life

Productivity

- Reduce cooling time

- Optimize cooling temperature

- Identify unsteady process conditions