Data technologies revolutionizing chocolate production

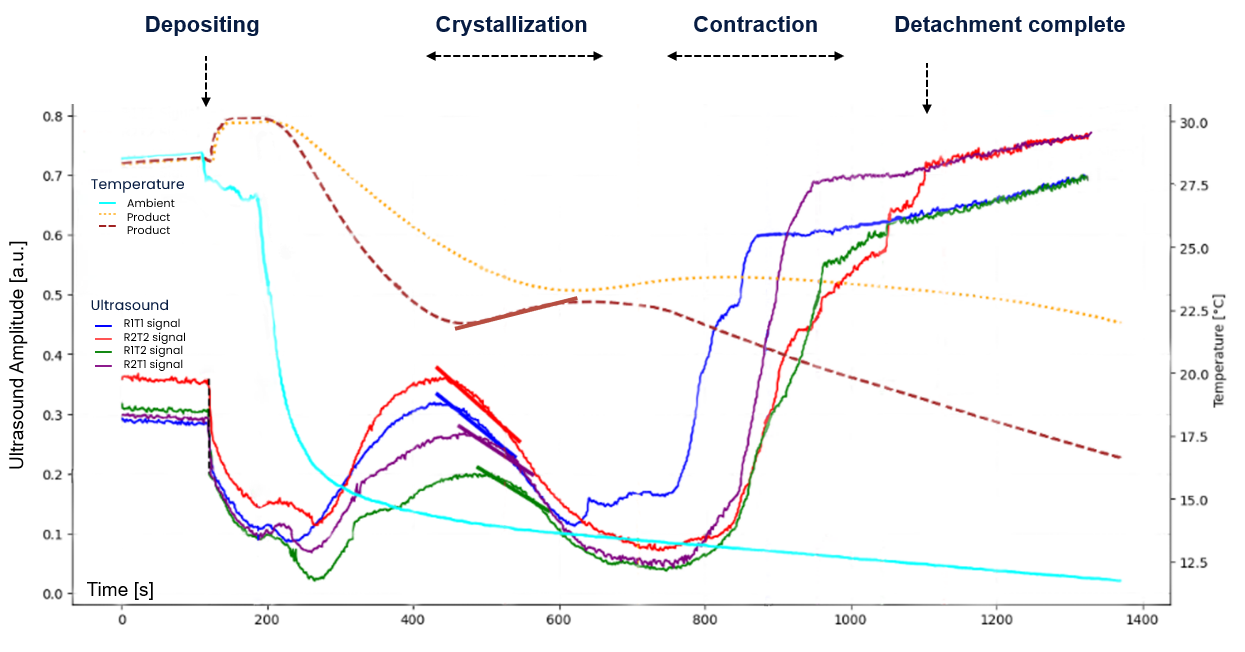

Chocolate structure measurement

- Crystal formation

- Degree of solidification

- Volume contraction

- Product-mould detachment

- Tempercurve

Real time monitoring from depositing to detachment

From guess-work to data-driven chocolate excellence

Main applications

Production process optimization

Define the right production parameters to optimize product quality and line efficiency: cooling time, cooling temperature, air velocity, mechanical treatments.

Raw material evaluation

Conduct entrance tests on raw materials and anticipate how to cope with quality variations.

New ingredient or CBE introduction

Measure the impact of new ingredients on the structural behavior of chocolate and optimize product recipes to achieve the highest quality.

Live view of chocolate solidification within a transparent mould and corresponding measurement of ultrasound amplitude

DetachLog brings intelligence to the complex chocolate structure kinetics

Already tested and adopted by renowned chocolate manufacturers

DetachLog at Max Felchlin AG

We've been using DetachLog at Max Fechlin AG for more than 5 years and we just installed it on an additional line in February 2025.

We use DetachLog to monitor the consistency of our cooling process and also to control the compliance of the specifications when inplementing a new moulding line.

We value the reliability of its measurements. It gives us a unique reading of the chocolate structure formation that we can't get with other measuring devices and it supports our commitment to high product quality.

Beat Styger

Chief Innovation and Quality Officer

Max Felchlin AG

Agenda

ISM 1-4.02.2026, Cologne

INTERPACK, 7-13.05.2026, Düsseldorf

Cohort 2025 EIT FAN

First Prize Winner

Proud to be part of the groundbreaking startups selected as change-makers across Europe to shape the future of food.